The principle of biogas production

Biogas is produced through anaerobic fermentation of organic matter and is a metabolic product of methane bacteria. The prerequisites for generating biogas, apart from oxygen deficiency, include a pH value between 6.5 and 7.5, and a temperature ranging from 15 to 25 (for thermophilic bacteria), 25 to 45 (for mesophilic bacteria), and 45 to 55 (for hyperthermophilic bacteria). The fermentation period for thermophilic bacteria is approximately 10 days, for mesophilic bacteria it is about 25 to 30 days, and for mesophilic bacteria it is approximately 90 to 120 days. Currently, most of the biogas fermentation facilities in use operate within the temperature range of mesophilic bacteria.

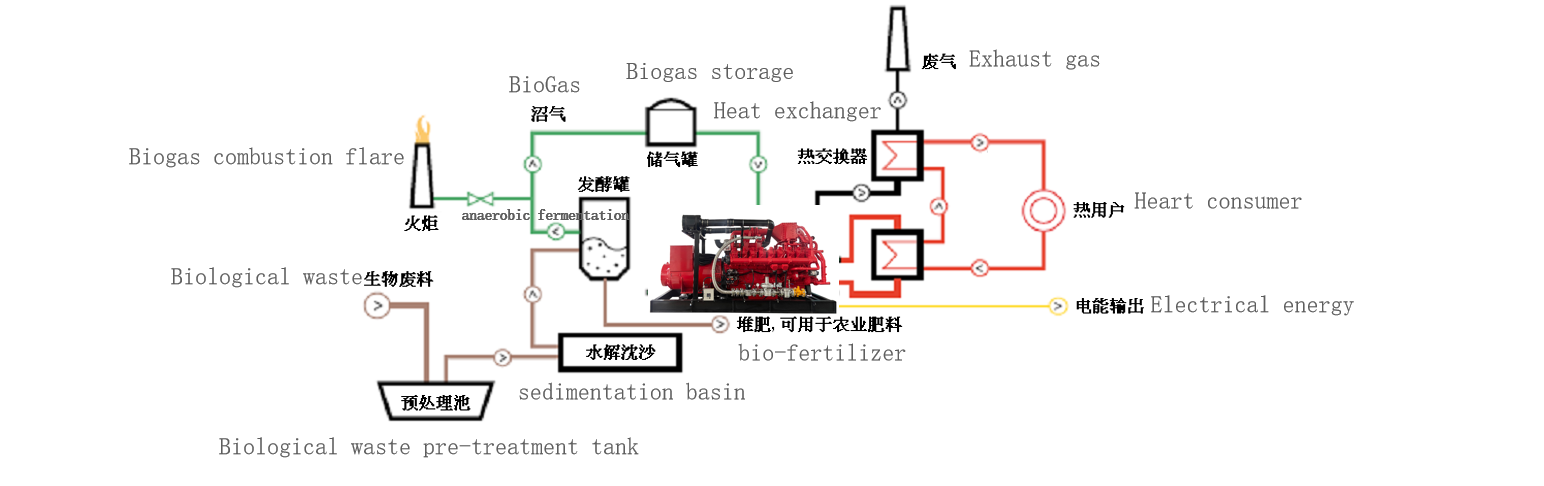

The process of biogas power generation

The organic substances are collected in a pre-treatment tank, where they are disinfected to eliminate harmful bacteria, and then transported to the fermentation tank for fermentation. The generated biogas is collected in a gas storage tank, with the aim of ensuring a stable gas output under different gas production volumes. Finally, the biogas is injected into the gas generator set. For safety considerations, it is recommended to install a flare as well. In case of excess gas, the surplus gas can be safely burned. The remaining substances after the biogas fermentation can be used as fertilizer. The mixed gas produced in the fermentation tank consists of 50% to 70% methane (CH4) and 30% to 50% carbon dioxide (CO2). This composition makes the biogas a high-energy and high-quality fuel for the gas generator set. The generated electricity can be used either at the treatment plant or sent to the public power grid. The heat energy can be used to heat the fermentation tank or supply heat to other facilities.