The combined heat and power (CHP) system is a system that can both provide heat and generate electricity.

The CHP system for gas-powered generators developed by TONTEK POWER. achieves an overall energy efficiency of over 90% by utilizing the waste heat generated during the operation of the engine. This highly efficient and cost-effective energy conversion method employs the gas engine combined heat and power system instead of separate power generation and heating equipment, successfully saving 40% of primary energy. Depending on the needs, as the implementation and integration of distributed energy supply schemes proceed, transmission and distribution losses will be significantly reduced or even eliminated.

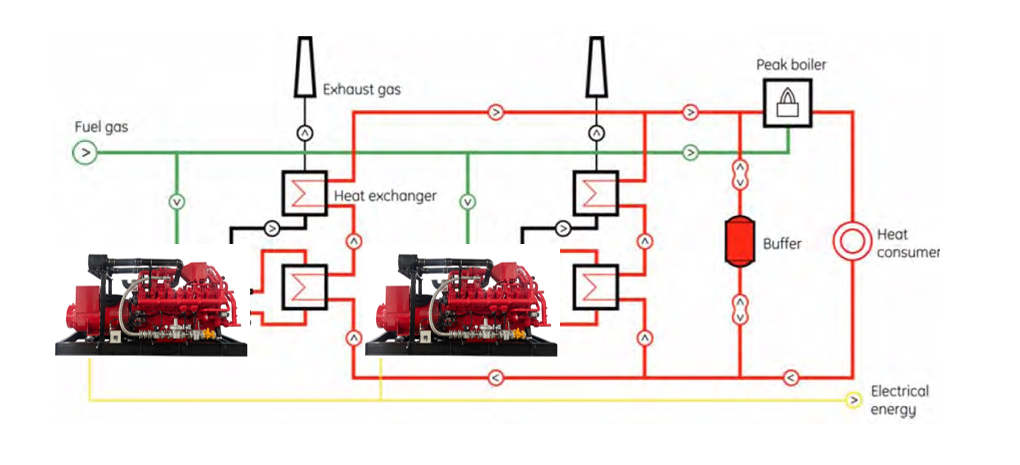

The cogeneration system for gas power generation units developed by TONTEK POWER. utilizes the waste heat generated during the operation of the engine to enhance the overall energy efficiency of the power plant. The basic structure of this system includes an engine/generator unit and a heat exchanger that utilizes the waste heat. This includes engine cooling water, lubricating oil, air/gas mixture device, and exhaust gas. Various residual heat sources are configured to provide the maximum benefits to the customers. Our solution enables flexible power generation and ensures the high reliability and availability of cogeneration.

The CHP system can also be used in conjunction with a supplementary combustion boiler system to meet peak heat demands. By connecting a heat storage device, the system’s operating time can be extended and its efficiency improved. The heat energy can be provided to customers as process steam or hot water.

Advantages:

1. The CHP system can simultaneously provide both electrical energy and thermal energy, with the overall energy utilization efficiency reaching up to 90%.

2. Highly integrated and modular design.